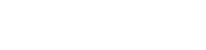

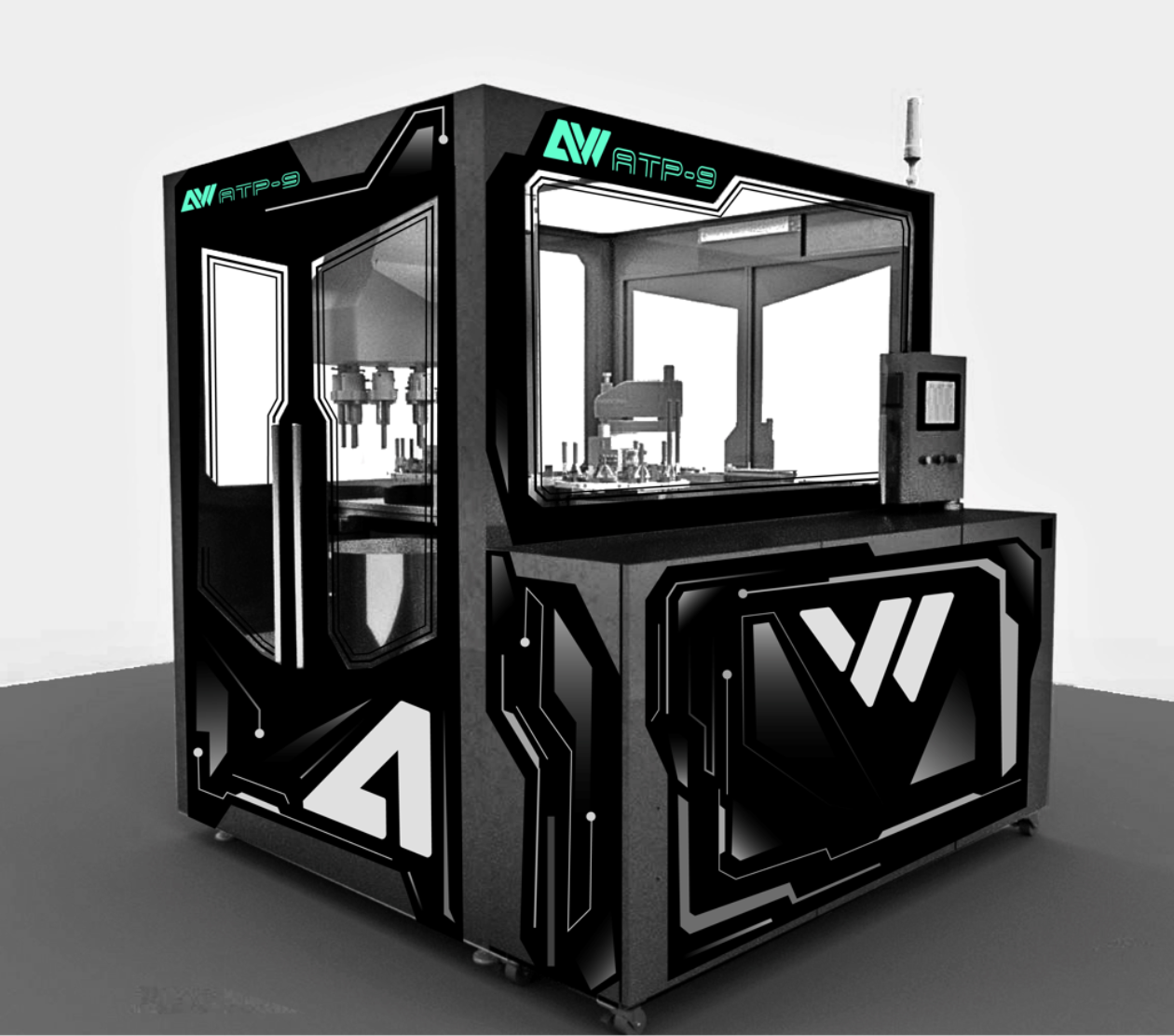

Fully Intelligent Finishing Machine

The ATP series provides automated high-quality machining and also ensures reliable processing results.

The workpiece clamping of the ATP series models is carried out automatically, so it is suitable for non-mass production and mass production lines.

The workpiece clamping of the ATP series models is carried out automatically, so it is suitable for non-mass production and mass production lines.

Product Advantages

1.World Premiere Fully Intelligent Finishing Machine, equipped with the Clip-type Multitasking Trays and Chucks that can provide 9 sets of grippers that can simultaneously or independently clamp the workpiece and automatically detect the clamping status.

2.Multi-station smart storage - Provide a quick trays change system to facilitate the operator to load and unload materials.

3.Independently Develop ATP1.0 HMI.

4.The Storage RFID Detection Device can be connected with the digital production system for automatically scheduling manufacturing process.

5.Provide φ3~16mm 50~120L a variety of sizes mixed manufacturing process. With the smart gripper, it can automatically detect the size of the workpiece without manual adjustment.

6.Independent self-rotating barrel with forward and reverse rotation and variable speed function.

7.During processing, the robotic arm can simultaneously load and unload materials from storage for saving time.

8.Provide 3 sets of passivation and polish device and 1 set of the cleaning device, to meet your processing needs in one take.

9.Equipped with intelligent media mixing device and automatic media mixing operation to improve process quality.

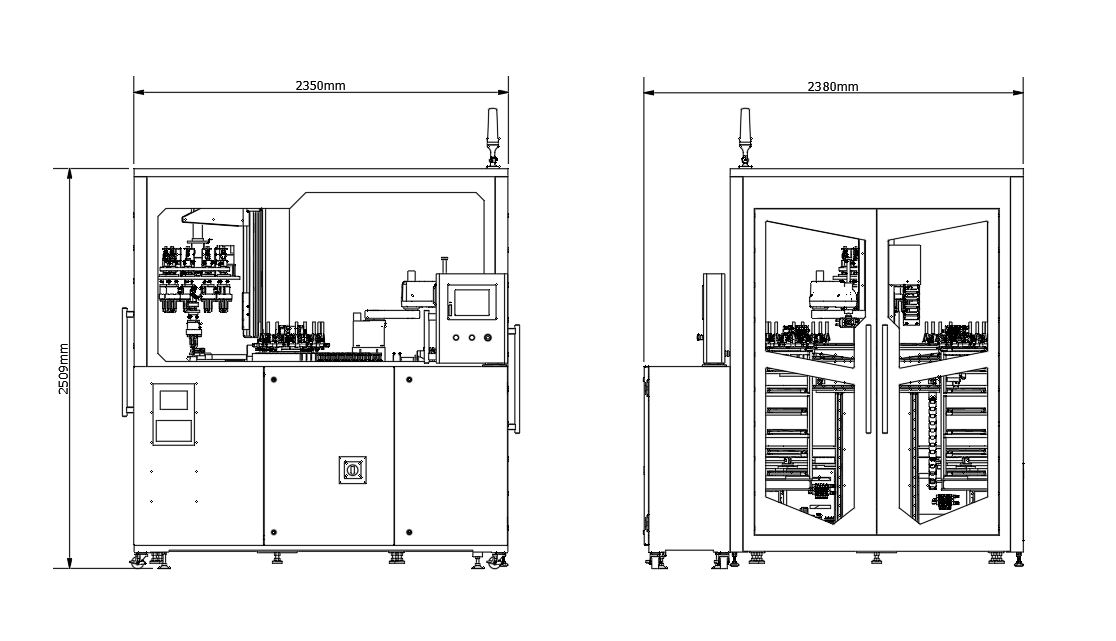

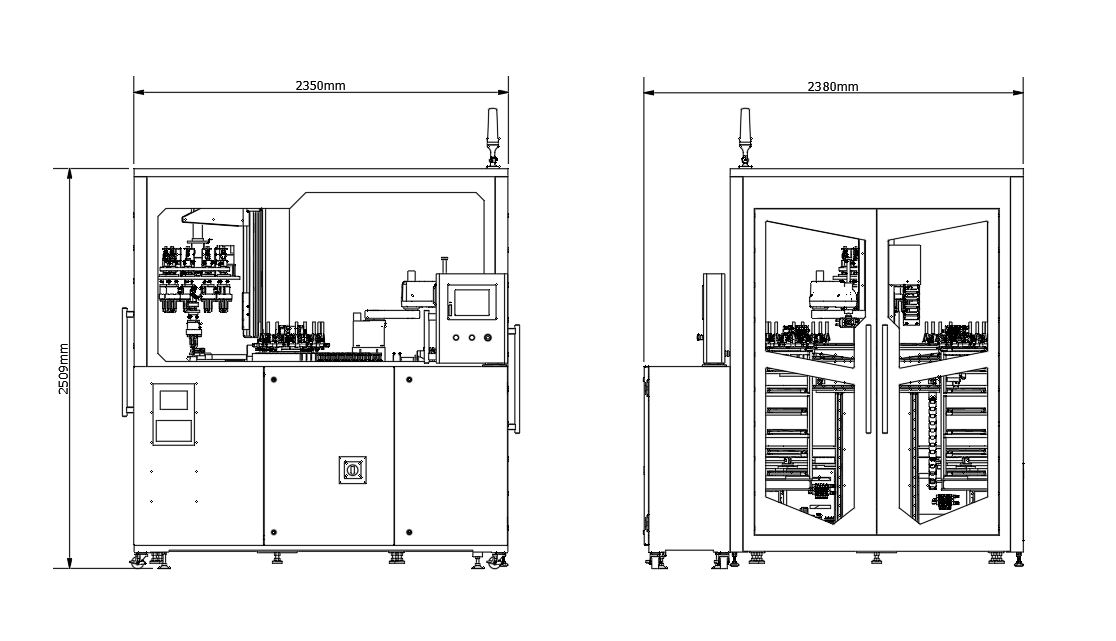

Specifications

1.World Premiere Fully Intelligent Finishing Machine, equipped with the Clip-type Multitasking Trays and Chucks that can provide 9 sets of grippers that can simultaneously or independently clamp the workpiece and automatically detect the clamping status.

2.Multi-station smart storage - Provide a quick trays change system to facilitate the operator to load and unload materials.

3.Independently Develop ATP1.0 HMI.

4.The Storage RFID Detection Device can be connected with the digital production system for automatically scheduling manufacturing process.

5.Provide φ3~16mm 50~120L a variety of sizes mixed manufacturing process. With the smart gripper, it can automatically detect the size of the workpiece without manual adjustment.

6.Independent self-rotating barrel with forward and reverse rotation and variable speed function.

7.During processing, the robotic arm can simultaneously load and unload materials from storage for saving time.

8.Provide 3 sets of passivation and polish device and 1 set of the cleaning device, to meet your processing needs in one take.

9.Equipped with intelligent media mixing device and automatic media mixing operation to improve process quality.

Specifications